1300 474 246

PRODUCTS

Richmond Max Series AMRs

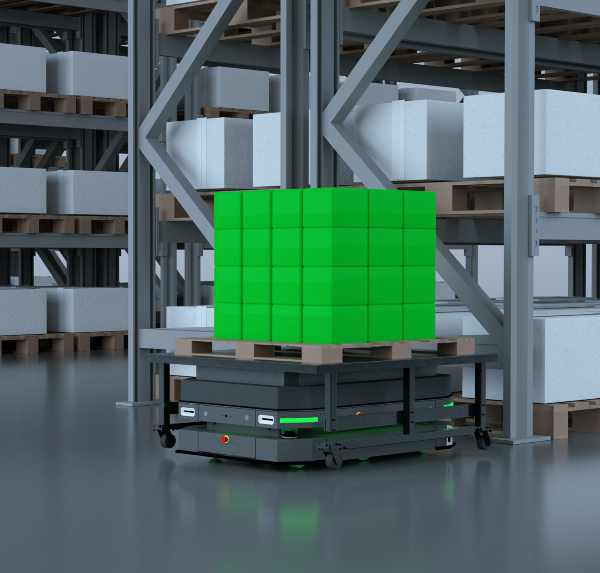

Richmond Max series brings all the flexibility of the Flex Series AMRs in a heavier duty package. The max features one of the highest load capacities offered among AMR-enabled picking solutions.

Richmond Max series brings all the flexibility of the Flex Series AMRs in a heavier duty package. The Max features one of the highest load capacities offered among AMR-enabled picking solutions. It also features a wide platform, making it perfect for handling the larger and heavier goods in your warehouse.

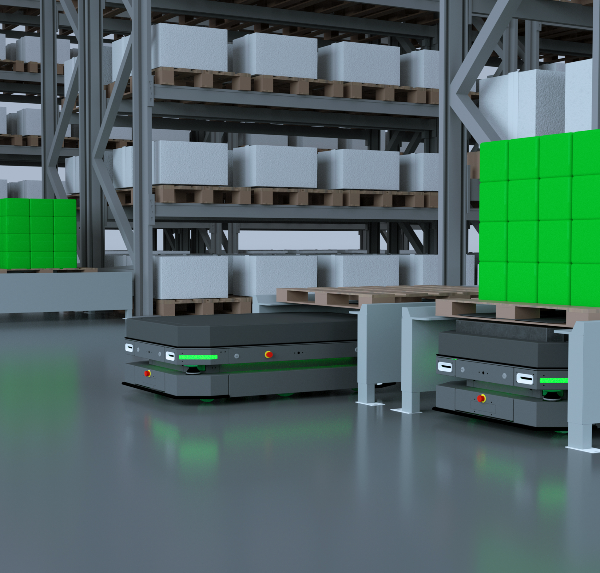

Max series AMRs are well suited to pallet and case picking for B2B retail store replenishment and B2C eCommerce fulfilment.

The Max L Series is equipped with a lifting function that allows the AMRs to autonomously locate pallets or larger racks and work with forklifts to automate receiving, putaway, replenishment, and shipping workflows.

Incorporating the latest LiDAR and vision technology coupled with industry-leading navigation software, each AMRs can be safe more than ever.

Maxium load surface up to 2,100x1,100 mm, making Max the most versatile AMR for your larger goods.

One of the highest load capacities offered among AMR-enabled picking solutions. High load capacity makes Max suitable for case- and pallet- loads.

Max can be configured with handheld devices, printers, etc.

Length

Width

Height

Turning Diameter

1,250 mm (49.21 in)

850 mm (35.46 in)

245 mm (9.64 in)

1,340 mm (52.75 in)

2,100 mm (82.67 in)

1,100 mm (43.30 in)

310 mm (12.20 in)

2,239 mm (88.14 in)

Weight

Max. Load Capacity

Load Surface

250 kg (551 lbs)

1,500 kg (3,306 lbs)

1,200×830 mm

(47.24×32.67 in)

700 kg (1,543 lbs)

2,500 kg (5,511 lbs)

2,100×1,100 mm

(82.67×43.30 in)

Lifting Height

60 mm (2.36 in)

145 mm (5.70 in)

Wi-Fi (IEEE 802.11a/b/g/n/ac)

Wi-Fi (IEEE 802.11ax)

Cellular Network (Public 4G/5G)

Yes

Optional

Optional

Navigation Mode

Positioning Mode

Natural / Road Network / Hybrid

Laser SLAM / Visual / Optional QR Code Navigation

Battery Type

Charging Mode

LFP

DC CC-CV

Audio

Light

Safety Bumper

Emergency Stop Button

CE Qualification

Yes

Yes

Yes

Yes

Yes

Below are some of the everyday applications that can be revolutionised by Max AMRs

Flex 600-ST

AMR

Richmond Flex 600-ST is designed for autonomous towing of cage trolleys to eliminate manual pushing of heavy carts.

Apex Series

AMRs

Richmond Apex series are the safest autonomous forklits, creating a safer and more productive warehouse floor.

Flex Series

AMRs

Richmond Flex series mobile robots are scalable, flexible, and adaptable to fit your mixed piece- and case-packing needs.

AMRs (Autonomous Mobile Robots) are a type of robot that uses built-in sensors and technology to autonomously move goods around factories and warehouses without the need for guides and markers.

AMRs are an adaptable, flexible, and accessible solution for improving order picking, packing, pallet transport, trolley/cage towing, production line handling, and more! With a good AMR in place, you will increase picking productivity and reducing wasted movement in your operations, making them and your team more efficient.